In today’s fast-paced world, electronic devices are an integral part of our daily lives. From smartphones to home appliances, electronic components power the technology we rely on. Whether you’re a product designer, engineer, or hobbyist, sourcing the best electronic components is crucial for ensuring the performance, reliability, and longevity of your creations. This ultimate guide provides valuable tips and tricks for finding the best parts and navigating the complex world of electronic components sourcing.

Page Contents

- Understanding Electronic Components

- Importance of Sourcing the Best Electronic Components

- Factors to Consider in Electronic Components Sourcing

- Researching and Identifying Electronic Components

- Evaluating Electronic Component Suppliers

- Managing Component Obsolescence and End-of-Life (EOL) Challenges

- Mitigating Risks and Ensuring Component Authenticity

- Collaborating with Contract Manufacturers and EMS Providers

- Benefits of Partnering with Contract Manufacturers

- Establishing Effective Communication Channels

- Quality Assurance and Supply Chain Integration

- Best Practices for Electronic Components Sourcing

- Conclusion

- Frequently Asked Questions (FAQs)

Understanding Electronic Components

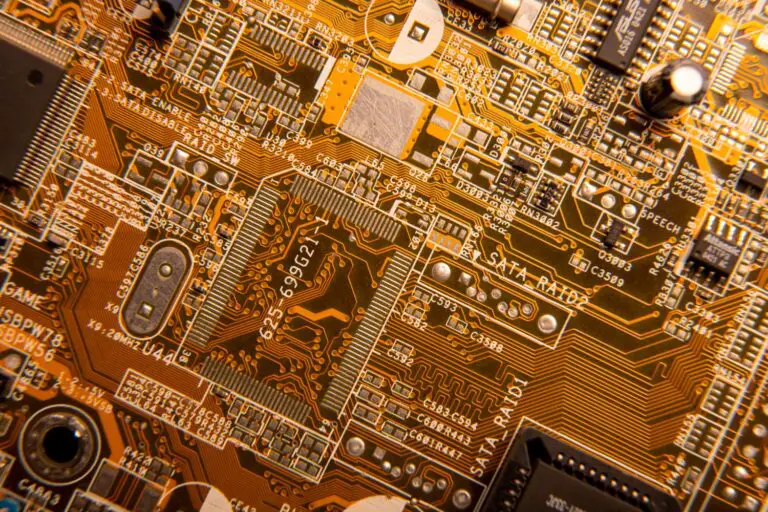

Definition and Importance of Electronic Components

Electronic components are the building blocks of electronic systems. They are individual devices or parts that perform specific functions within a circuit or system. These components can include resistors, capacitors, integrated circuits (ICs), connectors, and many others. The quality and reliability of these components directly impact the performance and durability of the end product.

Common Types of Electronic Components

Before diving into the sourcing process, it’s essential to familiarize yourself with common types of electronic components. This knowledge will help you make informed decisions when choosing the right parts for your projects. Some common types of electronic components include:

Resistors: They control the flow of current in a circuit.

Capacitors: They store and release electrical energy.

Diodes: They allow current to flow in one direction.

Transistors: They amplify and switch electronic signals.

Integrated Circuits (ICs): They contain multiple electronic components in a single package.

Importance of Sourcing the Best Electronic Components

Impact on Product Performance and Reliability

The quality of electronic components directly affects the performance and reliability of your end product. By sourcing high-quality components, you can ensure that your devices function optimally, delivering the desired performance and meeting customer expectations. Reliable components reduce the risk of malfunctions, failures, and costly repairs or replacements.

Cost Considerations and Return on Investment (ROI)

While sourcing electronic components, it’s important to strike a balance between quality and cost. Cheaper components may seem attractive from a budget perspective, but they can lead to compromised product performance and higher failure rates. On the other hand, investing in superior components may result in a higher upfront cost but can yield long-term benefits, such as improved product lifespan, reduced maintenance costs, and enhanced customer satisfaction.

Factors to Consider in Electronic Components Sourcing

To ensure the best sourcing outcomes, several factors should be taken into account:

Quality and Reliability

When selecting electronic components, prioritize quality and reliability. Look for components that adhere to industry standards and undergo rigorous testing and certification processes. Trusted manufacturers and suppliers with a proven track record of delivering reliable components should be preferred.

Compatibility and Interoperability

Ensure that the components you source are compatible with your existing systems or design requirements. Compatibility issues can lead to integration challenges, system failures, or suboptimal performance. Consider factors such as voltage ratings, pin configurations, form factors, and communication protocols to ensure seamless interoperability.

Availability and Lead Times

Consider the availability of components and their lead times, especially if you have strict project timelines. Some components may have long lead times or limited availability, which can delay production or project completion. Plan ahead, communicate with suppliers, and explore alternatives or second-source options to mitigate potential delays.

Supplier Reputation and Support

Research and evaluate the reputation and support provided by electronic component suppliers. Choose suppliers with a solid reputation for delivering quality products and excellent customer service. A responsive and knowledgeable supplier can provide valuable technical support, assist in component selection, and offer prompt assistance in case of any issues or concerns.

Researching and Identifying Electronic Components

To effectively source electronic components, you need to conduct thorough research and identify the right parts for your project. Here are some tips for this process:

Industry Standards and Specifications

Understand the industry standards and specifications relevant to your project. This knowledge will help you select components that meet the required performance, safety, and compliance standards. Consult industry guidelines, datasheets, and technical documentation to make informed decisions.

Online Component Databases and Distributors

There are many websites that can be used for electronic components sourcing. Here are some popular websites that you can consider:

- Digi-Key Electronics : This is one of the largest electronic component distributors in the world, offering a wide range of components from various manufacturers.

- Mouser Electronics : This website offers a comprehensive selection of electronic components and provides access to inventory from hundreds of manufacturers.

- Arrow Electronics : This is another major distributor of electronic components, offering a broad range of products and services to customers around the world.

- RS Components : This website offers an extensive selection of electronic components, tools, and accessories for engineers and other professionals.

- Newark : This website offers a wide range of electronic components from various manufacturers, with a focus on serving engineers and other professionals.

- Jameco Electronics : This website offers a comprehensive selection of electronic components sourcing, as well as a range of tools and supplies for electronic hobbyists and enthusiasts.

- Avnet : This is a global technology solutions provider that offers a wide range of electronic components and related products and services to customers around the world.

Collaboration with Design Engineers

Collaborate with design engineers to understand the specific component requirements for your project. Design engineers possess in-depth knowledge and expertise in selecting components that align with the desired functionality, performance, and reliability of the system. Engage in regular communication and leverage their expertise to identify the most suitable components.

Evaluating Electronic Component Suppliers

Selecting reliable suppliers is crucial for successful electronic components sourcing. Consider the following factors when evaluating suppliers:

Assessing Supplier Reliability and Reputation

Evaluate suppliers based on their reliability, reputation, and industry standing. Read customer reviews, testimonials, and ratings to gain insights into their track record. Additionally, inquire about their quality control processes, certifications, and adherence to industry standards.

Conducting Supplier Audits and Qualification Processes

Perform supplier audits and qualification processes to ensure that suppliers meet your specific requirements. This may involve assessing their manufacturing facilities, quality management systems, and compliance with relevant regulations. A thorough evaluation process helps ensure that you establish partnerships with trustworthy and capable suppliers.

Comparing Pricing and Lead Times

Obtain quotes from multiple suppliers and compare pricing and lead times. While cost is an important consideration, it should not be the sole determining factor. Look for a balance between competitive pricing and reliable delivery schedules. Inquire about volume discounts, bulk pricing, and potential cost savings in the long run.

Managing Component Obsolescence and End-of-Life (EOL) Challenges

Electronic components often face obsolescence issues, as technology advances and manufacturers discontinue certain parts. Managing component obsolescence is vital to avoid supply chain disruptions and maintain product longevity. Consider the following strategies:

Understanding Product Lifecycle Management (PLM)

Implement a robust Product Lifecycle Management (PLM) system to track the lifecycle stages of your products and the associated electronic components. This allows you to proactively identify components at risk of obsolescence and plan for suitable alternatives or last-time buys.

Proactive Obsolescence Management Strategies

Stay informed about component lifecycle information provided by manufacturers and industry sources. Proactively identify components nearing end-of-life and work closely with suppliers to develop obsolescence management strategies. This may involve finding alternate components or redesigning products to accommodate newer technologies.

Identifying Alternative or Second-Source Components

Maintain a list of approved alternate or second-source components for critical parts prone to obsolescence. This ensures a backup supply option if the primary component becomes obsolete. Regularly assess the availability and compatibility of these alternatives.

Mitigating Risks and Ensuring Component Authenticity

Electronic component counterfeit and gray market risks can jeopardize the performance and reliability of your products. To mitigate these risks and ensure component authenticity, consider the following measures:

Counterfeit Electronic Components and Gray Market Risks

Counterfeit components are unauthorized copies or imitations of genuine components. The gray market refers to the unauthorized or unofficial distribution channels through which components may be sold. These pose risks in terms of quality, reliability, and compatibility. Be vigilant and take proactive steps to avoid counterfeit components and unauthorized sourcing channels.

Supplier Verification and Certifications

Work with suppliers who have robust quality management systems, supply chain transparency, and certifications such as ISO 9001. Conduct thorough due diligence to verify the authenticity and legitimacy of suppliers, especially when dealing with expensive or critical components.

Implementing Quality Control and Inspection Processes

Implement stringent quality control and inspection processes to validate the authenticity of electronic components. This may involve visual inspections, functional testing, and verification of unique identifiers such as serial numbers or holograms. Invest in reliable testing equipment and collaborate with trusted third-party testing labs when necessary.

Collaborating with Contract Manufacturers and EMS Providers

Partnering with contract manufacturers and Electronics Manufacturing Services (EMS) providers can offer several advantages in electronic components sourcing:

Benefits of Partnering with Contract Manufacturers

Contract manufacturers and EMS providers specialize in managing the procurement of electronic components and offer expertise in supply chain management. They often have established relationships with trusted suppliers, ensuring access to high-quality components and competitive pricing. Additionally, they have the resources and capabilities to handle large-scale production and can assist in streamlining the manufacturing process.

Establishing Effective Communication Channels

Maintain open and effective communication channels with contract manufacturers and EMS providers. Clearly communicate your component requirements, quality expectations, and project timelines. Regularly update them on any changes or specific considerations to ensure smooth collaboration and minimize misunderstandings.

Quality Assurance and Supply Chain Integration

Collaborate closely with contract manufacturers and EMS providers to establish robust quality assurance processes. Define quality control standards, conduct regular inspections, and implement supply chain integration measures to ensure the traceability and authenticity of components throughout the manufacturing process.

Best Practices for Electronic Components Sourcing

Adopting best practices can enhance your electronic components sourcing process and optimize outcomes. Consider the following tips:

Building Strong Supplier Relationships

Nurture strong relationships with your component suppliers. Regularly communicate with them, provide feedback on their performance, and collaborate on continuous improvement initiatives. A mutually beneficial partnership ensures better support, priority access to components, and potential cost-saving opportunities.

Continuously Monitoring Industry Trends

Stay updated on the latest industry trends, technological advancements, and emerging components. Attend trade shows, conferences, and webinars to expand your knowledge and network with industry experts. Being aware of new components and technologies allows you to make informed decisions and stay ahead of the competition.

Embracing Design for Supply Chain (DFSC) Principles

Incorporate Design for Supply Chain (DFSC) principles into your product development process. Involve supply chain and sourcing professionals early on to optimize component selection, minimize sourcing challenges, and streamline the manufacturing process. DFSC ensures that components are readily available, cost-effective, and meet your specific project requirements.

Conclusion

Sourcing the best electronic components is crucial for ensuring the performance, reliability, and success of your electronic devices and systems. By understanding the importance of quality, considering factors like compatibility and availability, and implementing effective sourcing strategies, you can optimize your component selection process. Collaborating with reliable suppliers, leveraging the expertise of contract manufacturers, and adopting best practices will further enhance your sourcing efforts. Stay proactive in managing component obsolescence, mitigating risks, and ensuring authenticity. With careful attention to electronic components sourcing, you can build superior products and gain a competitive edge in the market.

Frequently Asked Questions (FAQs)

How can I ensure the quality of electronic components?

Prioritize suppliers with a strong reputation, industry certifications, and rigorous quality control processes. Conduct thorough inspections and functional testing to validate component quality.

What should I do if a component becomes obsolete?

Proactively manage component obsolescence by staying informed about product lifecycles, identifying alternatives, and collaborating with suppliers and contract manufacturers to develop suitable strategies.

How can I verify the authenticity of electronic components?

Verify suppliers’ legitimacy, request documentation, and certifications. Implement quality control measures, such as visual inspections and testing. Work with trusted suppliers and consider third-party testing when necessary.

What are the benefits of partnering with contract manufacturers?

Contract manufacturers offer expertise in supply chain management, access to trusted suppliers, and streamlined production processes. They can help optimize component sourcing and manufacturing efficiency.