Designing a Switched Mode Power Supply (SMPS) can be very challenging especially for a new Power Electronics Engineer as it requires to consider a lot of criteria to design one. In this blogpost, I will explain some tips and tricks which will help you to understand the process of designing a switched mode power supply in a better way.

Page Contents

What is a Switched Mode Power Supply (SMPS)?

A Switched-Mode Power Supply abbreviated as SMPS, is an electronic power supply that converts electrical power from one form to another, using a switching regulator. SMPS is typically more efficient than traditional linear power supplies, as it uses a switching transistor to rapidly switch the input voltage on and off, and then filters the output using capacitors and inductors. SMPS is used in many electronic devices such as computers, TVs, LED lighting and power adapters. They offer high efficiency, compact size, and superior performance compared to traditional linear power supplies. As a result, SMPS design has become an integral part of electronic design.

Why do We use Switched Mode Power Supply?

There are several reasons why Switched Mode Power Supply is commonly used in electronic devices:

- Efficiency: SMPS is typically more efficient than traditional linear power supplies, as it wastes less energy as heat which makes it a cost-effective and environmentally friendly.

- Size and Weight: SMPS is generally smaller and lighter than linear power supplies, making it easier to fit into compact devices.

- Flexibility: SMPS can be designed to work with a wide range of input voltages and frequencies which makes it suitable for using in many countries and regions.

- Regulated Output: SMPS provides a regulated output voltage that is less affected by input voltage variations and load changes, ensuring stable and consistent performance.

- Cost: Although the initial cost of an SMPS may be higher than that of a linear power supply, its higher efficiency and longer lifespan can result in cost savings over time.

Tips:

Understanding the Basics

The first step in designing a Switched Mode Power Supply is to understand the basic principles of operation. An SMPS operates by switching a power transistor or a mosfet on and off at high frequencies, typically in the range of 50 kHz to several MHz. This switching makes power supply to convert high voltage, low current input power into low voltage, high current output power with high efficiency and vice-versa too, depending on application.

One of the critical components of a Switched Mode Power Supply is the transformer, which allows for isolation between the input and output circuits. The transformer also provides voltage conversion between the input and output circuits. Proper transformer design is crucial for the success of an SMPS.

Choosing the Right Topology

There are several Switched Mode Power Supply topologies to choose from, including flyback, forward, push-pull, and half-bridge. Each topology has some advantages and some disadvantages and the choice of topology depends completely on the application.

The flyback topology is the simplest and most commonly used Switched Mode Power Supply topology. It is ideal for low power applications and provides isolation between the input and output circuits. The forward topology is best suited for high power applications and provides excellent regulation. The push-pull and half-bridge topologies are ideal for medium power applications and provide high efficiency.

Component Selection

Choosing the right components is critical to the success of an SMPS design. The power transistor, diode, and capacitor are essential components of an SMPS. The power transistor should be selected based on the application requirements, including the maximum output power, input voltage range, and switching frequency.

The diode should have a fast recovery time to reduce the switching losses. The capacitor should be chosen based on the application requirements and should have low ESR and ESL to reduce the ripple voltage and noise.

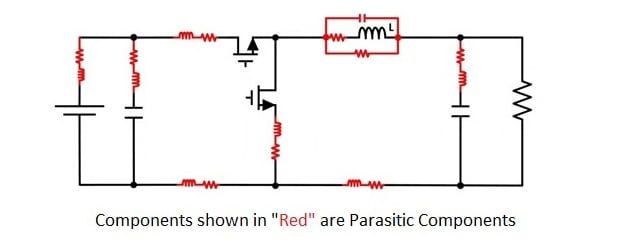

Layout Considerations in Switched Mode Power Supply

Proper layout is critical to the success of an SMPS. The layout should be designed to minimize the loop area and reduce the parasitic inductance and capacitance. The placement of components should be optimized to reduce the loop area, and the routing of traces should be kept short and direct.

The placement of the transformer is also critical to the success of an SMPS design. The transformer should be placed away from the switching components to reduce the coupling between the primary and secondary windings.

Testing and Validation

Testing and validation are critical to the success of an SMPS design. The SMPS should be tested under various operating conditions to ensure that it meets the application requirements. The testing should include input and output voltage regulation, efficiency, and transient response.

The SMPS should also be tested for electromagnetic compatibility (EMC) to ensure that it does not interfere with other electronic devices or cause interference.

Conclusion

Switched mode power supplies are essential components in modern electronic devices. Designing an Switched Mode Power Supply (SMPS) requires an understanding of the basic principles of operation, choosing the right topology, component selection, layout considerations, and testing and validation. By following these tips and tricks, designers can create efficient and reliable SMPS designs that meet the application requirements.