Signal integrity is the lifeblood of any printed circuit board (PCB) design. The challenges of signal integrity becomes more prominant in high speed PCB Designs. In this article, we will understand the challenges for signal integrity and best practices for maintaining signal integrity on a PCB.

Understanding Signal Integrity

Signal integrity is the transmission of signal from transmitter to receiver in its purest form. Any distortion, degradation or reflection in the signal is considered as signal integrity issue. There are certain rules for maintaining signal integrity while designing the PCB. Ignoring signal integrity can lead to multiple issues in PCB, starting from data corruption to even complete system failure. For high speed PCBs without signal integrity, there are very high chances that PCB will not work as intended.

How to maintain signal integrity on a PCB?

There are multiple factor that can ensure signal integrity on a PCB, Let us discuss them in details:

1. Planned PCB Layer Stack-up

Proper PCB Layer stack-up is the first step for signal integrity in the PCB. Proper planning of ground, power planes and signal planes is crucial to help avoiding many potential issues just from the origin. Keeping the reference plane nearest to signal layer of controlled impedance traces is essential.

2. Proper Components Placement

Proper components placement ensures that power switching components and digital components are seperated from each other to avoid unwanted noise coupling on digital signals. Decoupling capacitors help stabilizing voltage and mitigating power supply noise. Strategically placing decoupling capacitors near power-hungry components is essential. This simple practice can prevent voltage fluctuations and enhance signal integrity.

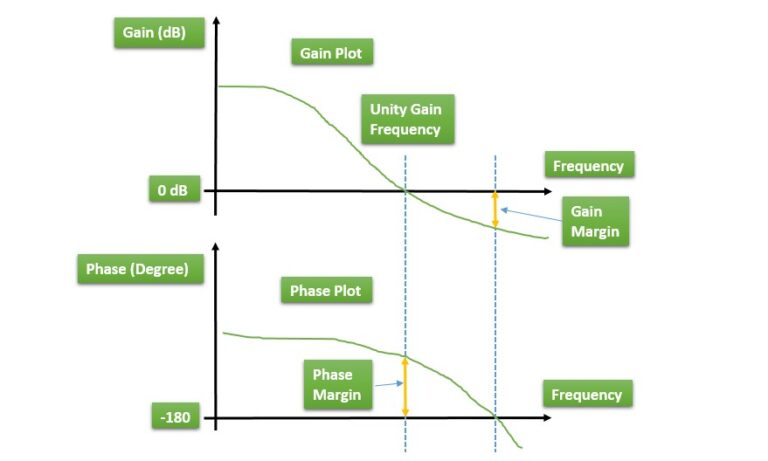

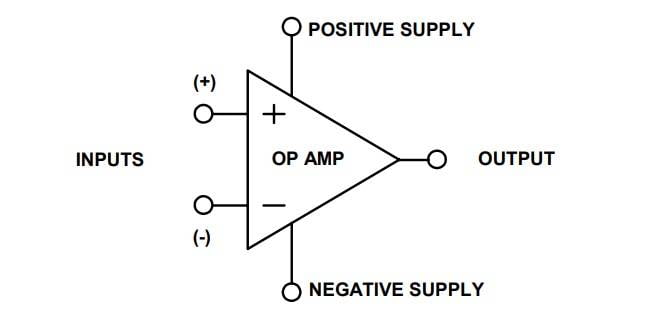

3. Impedance Matching

Impedance matching is the harmony in the electrical relationship between transmitter and receiver. Achieving impedance matching is crucial for preventing signal reflections and ensuring efficient signal transfer. Impedance matching can be achieved by properly calculating the required trace width and seperation also (in case of differential traces) as per distance from reference plane. Many calculators are available online to calculate single ended as well as differential impedance.

4. Length Matching of timing-critical signals

In every high speed board, there are some timing critical signals that needs to be in synch with each other as per timing, to ensure that lengths of such signal traces are needed to be tightly matched. Many advanced PCB design tools provide the options for length matching, using that one can ensure proper length matching for proper signal integrity.

5. Avoid Unintentional Electromagnetic Coupling (Crosstalk)

When signals traverse in a high-speed PCB traces, unwanted noise can couple on the adjacent traces and significantly impact signal integrity. Employing proper trace routing techniques reduces signal distortion and electromagnetic interference. Minimize stubs, maintain appropriate trace widths and separation to minimize crosstalk.

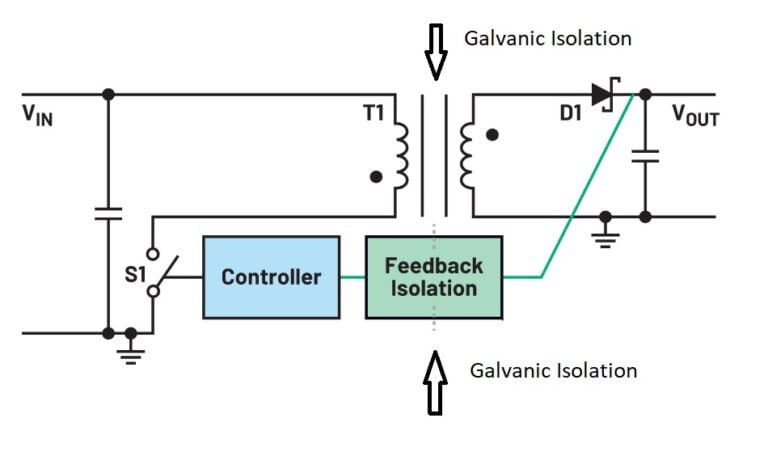

6. Address Ground Bounce

Ground planes play an important role in signal integrity. They act as a reference point for signals, minimizing noise and providing a stable electrical reference. When designing ground planes, ensure a continuous and uninterrupted structure, adhering to best practices for optimal performance.

7. Avoid EMI

Identifying and mitigating noise sources is pivotal. Shield critical traces from noisy components and employ signal integrity best practices like proper grounding. This proactive approach minimizes the impact of external factors on signal quality.

8. Use of Advanced PCB Design Tools

In the modern PCB designs, utilizing advanced tools is a necessity. Choose tools that offer features like impedance calculation, 3D modeling, and signal integrity analysis. Investing in the right tools empowers you to create designs with precision.

9. Signal Integrity Simulation

Potential signal integrity issues can be predicted before physical implementation using signal integrity simulation. Simulation tools allow you to analyze and optimize your design virtually, reducing the likelihood of post-production surprises. Embrace simulation as a proactive measure in your design process.

10. Design Reviews and Testing

The journey doesn’t end with the completion of your design. Regular design reviews and testing are indispensable. These practices avoids potential signal integrity issues and allow for timely corrections. Embrace a culture of scrutiny and refinement.

11. Continuous Learning and Adaptation

The field of PCB design is dynamic, with technology evolving rapidly. Stay informed about the latest advancements, attend conferences, and engage with the community. A mindset of continuous learning ensures your designs remain at the forefront of innovation.

Conclusion

In the high-speed PCB design, signal integrity is the thread that binds success. Implementing the best practices outlined here ensures your journey as a PCB designer is marked by reliability, efficiency, and innovation.

FAQs

To maintain the signal quality during propagation by avoiding signal degradation is signal integrity.

The analysis to get the idea of signal quality using advanced PCB simulation tools is called signal analysis.

Signal integrity is important for proper working of high-speed circuit boards.

The 3W rule suggests, if two traces are routed adjacent to each other, the spacing between them should be at least 3 times the width of the traces.