Almost all of us, who have studied Physics, Electrical, or Electronics know about the working of a diode i.e. it conducts current in forward bias and blocks the flow of current when reverse biased. You may be wondering why for this simple single application, different types of diodes exist. When someone needs to design a practical electronic circuit, things are not so simple. Nowadays circuits are required to be much smaller in size and at the same time need to be fast and features-loaded with the highest achievable efficiency. Thus many different techniques and components are used to achieve that, the Schottky diode is also a type of component that fulfills this requirement to some extent. In this article, we will explore the Schottky diodes, their working principle, applications, and advantages in detail.

Page Contents

- What is a Schottky Diode?

- Symbol of Schottky Diode

- Working Principle

- Advantages

- Applications

- Factors affecting Performance

- Fabrication

- Schottky Diodes in Modern Electronics

- Ongoing Research and Advancements

- Selection Criteria for Choosing the Right Schottky Diode

- Schottky Diode vs Regular Diode vs Zener Diode

- Silicon Carbide (SiC) Schottky Diode

- Conclusion

- FAQs

What is a Schottky Diode?

A Schottky diode, named after physicist Walter H. Schottky, is a special type of diode that has a distinct metal-semiconductor junction. Unlike conventional diodes that use a P-N junction, Schottky diodes utilize a metal layer on a semiconductor material to form this junction. This metal-semiconductor junction results in a lower forward voltage drop and faster switching speeds.

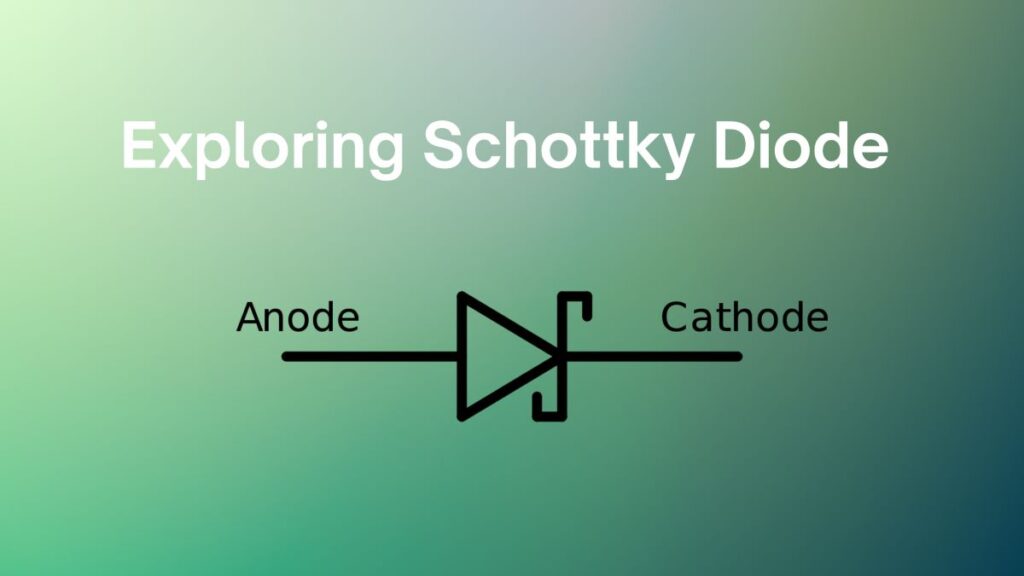

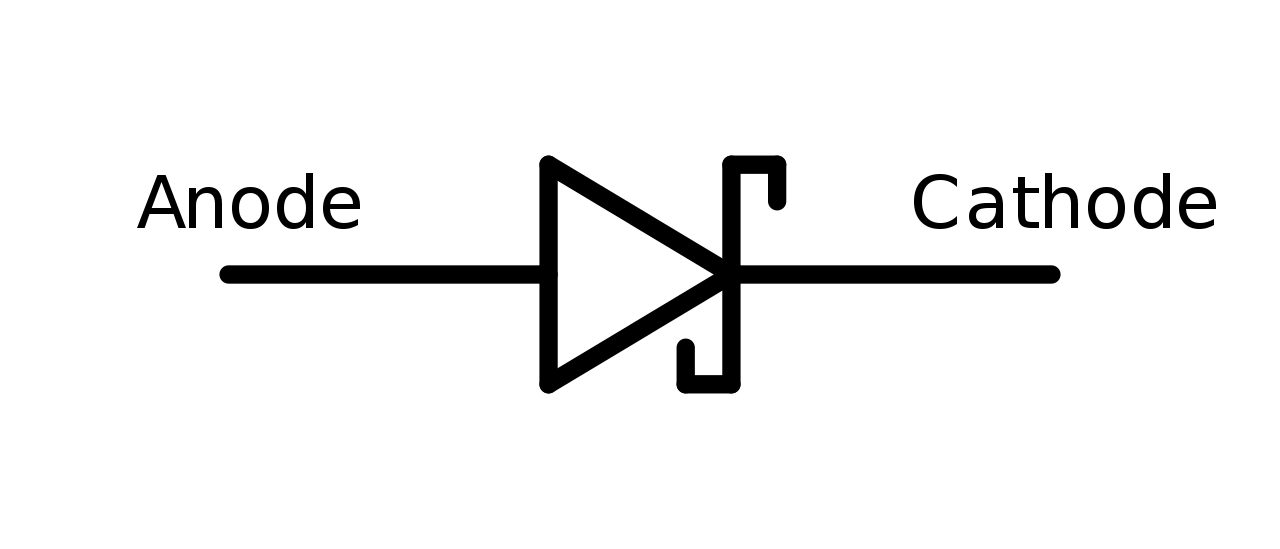

Symbol of Schottky Diode

The symbol for a Schottky diode typically resembles a regular diode symbol with a difference in the lines or shapes that represent the semiconductor and metal junction. It’s usually shown as a triangle attached to a line, indicating the semiconductor and metal junction, respectively. The arrow inside the triangle signifies the direction of current flow. This symbol reflects the unique structure of a Schottky diode, distinguishing it from other types of diodes. Below is the symbol of schottky diode:

Working Principle

Metal-Semiconductor Junction

The core of a Schottky diode’s operation lies in its metal-semiconductor interface. This junction, formed between the metal and semiconductor materials, enables the unimpeded flow of electrons, offering a lower resistance compared to standard diodes.

Lower Forward Voltage Drop

One of the defining characteristics of Schottky diodes is their notably low forward voltage drop, typically around 0.3 volts. This is very low in comparison with traditional diodes. The lower voltage drop in Schottky diodes results in reduced power losses and heat generation, making them highly efficient in various applications.

Advantages

Enhanced Efficiency

The primary advantage of Schottky diodes is their efficiency in power management. The lower forward voltage drop minimizes energy dissipation, leading to improved overall efficiency in electronic circuits.

Fast Switching Speeds

Schottky diodes excel in high-frequency applications due to their ability to switch between conducting and non-conducting states at a rapid pace. This feature is very important in circuits where fast response times are crucial.

Applications

Power Rectification

Schottky diodes find extensive use in power rectification applications. Their low forward voltage drop makes them ideal for efficiently converting alternating current (AC) to direct current (DC) in power supplies and voltage regulators.

RF and Microwave Circuits

The fast switching speeds of Schottky diodes make them indispensable in radio frequency (RF) and microwave circuits. Their quick modulation and demodulation capabilities contribute to the fast transmission of signals in communication systems.

Solar Energy Utilization

When we talk about renewable energy, Schottky diodes play a role in solar panels. Their efficiency in converting solar energy into electricity, combined with their low forward voltage drop, enhances the overall performance of solar energy systems.

Factors affecting Performance

Material Selection Impact

The choice of materials significantly influences Schottky diodes’ performance. Metals such as platinum, chromium, and titanium are commonly used due to their excellent conductivity and compatibility with semiconductor materials like silicon.

Temperature’s Influence on Performance

Temperature variations can impact Schottky diode performance, affecting parameters such as forward voltage drop and leakage current. Understanding and accounting for these effects are crucial in designing reliable circuits.

Fabrication

The manufacturing process of Schottky diodes involves several precise steps. These include cleaning and preparing the semiconductor surface, depositing the metal layer, and forming the metal-semiconductor junction using techniques like sputtering or evaporation.

Schottky Diodes in Modern Electronics

The versatility of Schottky diodes has led to their integration into various electronic devices. From smartphones to high-end computers, their unique characteristics contribute to the efficiency and performance of modern technologies.

Ongoing Research and Advancements

Continuous research is focused on enhancing Schottky diodes’ performance. Addressing challenges such as reverse leakage current and optimizing thermal characteristics are key areas of exploration. Advancements in materials and manufacturing techniques hold the promise of even more efficient and reliable diodes in the future.

Selection Criteria for Choosing the Right Schottky Diode

Selecting the appropriate Schottky diode involves considering factors such as voltage ratings, forward voltage drop, switching speeds, and temperature ranges. Ensuring alignment with specific application requirements is crucial for optimal performance.

Schottky Diode vs Regular Diode vs Zener Diode

Regular Diode:

Structure: A regular diode consists of a P-N junction formed by doping a semiconductor material.

Forward Voltage Drop: Typically has a higher forward voltage drop, around 0.7 volts for silicon diodes.

Switching Speed: Switching speeds are comparatively slower than Schottky diodes due to the nature of the P-N junction.

Applications: Commonly used for rectification, voltage regulation, and signal demodulation in various electronic circuits.

Schottky Diode:

Structure: Utilizes a metal-semiconductor junction instead of a P-N junction, enhancing conductivity.

Forward Voltage Drop: Known for its lower forward voltage drop, typically around 0.3 volts, resulting in reduced power loss.

Switching Speed: Excels in high-frequency applications due to faster switching speeds facilitated by the metal-semiconductor junction.

Applications: Ideal for applications where efficiency and high-speed switching are crucial, such as RF circuits, power rectification, and solar energy utilization.

Zener Diode:

Structure: Zener diodes are constructed with a P-N junction, similar to regular diodes, but designed to operate in the breakdown region.

Voltage Regulation: Primarily used for voltage regulation by maintaining a constant voltage across their terminals when operated in reverse breakdown.

Voltage Drop: Exhibits a relatively higher forward voltage drop compared to Schottky diodes.

Applications: Frequently employed in voltage regulators, surge protectors, and in circuits requiring stabilized voltage levels.

Schottky diodes stand out for their lower forward voltage drop and faster switching speeds compared to regular diodes, making them more efficient in specific applications. Whereas Zener diodes specialize in voltage regulation through reverse breakdown, maintaining a stable voltage.

Silicon Carbide (SiC) Schottky Diode

A silicon carbide (SiC) Schottky diode is a type of Schottky diode that utilizes silicon carbide as the semiconductor material instead of conventional silicon. This substitution offers several advantages:

Higher Breakdown Voltage: SiC materials can handle higher electric fields, allowing for higher breakdown voltages compared to traditional silicon-based diodes.

Lower Forward Voltage Drop: Silicon carbide Schottky diodes exhibit even lower forward voltage drops than standard silicon-based Schottky diodes, leading to reduced power losses and increased efficiency.

High-Temperature Operation: SiC materials can operate at higher temperatures without significant performance degradation, making them suitable for high-temperature applications.

Fast Switching Speeds: Due to their inherent properties, SiC Schottky diodes enable faster switching speeds, ideal for applications requiring rapid transitions.

Reduced Reverse Recovery Time: SiC diodes have minimal reverse recovery times compared to silicon-based diodes, contributing to higher efficiency and lower switching losses.

These characteristics make silicon carbide Schottky diodes particularly attractive for applications demanding high efficiency, high-frequency operations, and those requiring performance in harsh environments or elevated temperatures, such as in power supplies, electric vehicles, renewable energy systems, and aerospace technology.

Conclusion

In conclusion, Schottky diodes represent a significant advancement in semiconductor technology. Their unique design and characteristics make them indispensable in various electronic applications, contributing to enhanced efficiency and performance.

FAQs

How does a Schottky diode differ from a standard diode?

Schottky diodes utilize a metal-semiconductor junction, leading to lower forward voltage drops and faster switching compared to PN junction diodes.

What are the primary applications of Schottky diodes?

They are extensively used in power rectification, RF circuits, solar panels, and high-frequency applications due to their efficiency and fast response times.

What factors affect Schottky diode performance?

Material choices and temperature variations significantly impact their performance, influencing parameters like forward voltage drop and leakage current.

How are Schottky diodes fabricated?

The fabrication involves precise steps such as semiconductor surface preparation, metal deposition, and forming the metal-semiconductor junction using specialized techniques.

What considerations are crucial when selecting a Schottky diode?

Voltage ratings, forward voltage drop, switching speeds, and temperature ranges should be considered to ensure optimal performance in specific applications.

What challenges do Schottky diodes face?

Thermal considerations and reverse leakage currents pose challenges, requiring ongoing research for mitigation.