Robotic automation refers to the use of robots and intelligent machines to perform tasks and processes with minimal human intervention. Robotic automation aims to improve productivity, accuracy, and efficiency in various industries, ranging from manufacturing and logistics to healthcare and customer service. By automating repetitive or dangerous tasks, robotic automation streamlines operations, reduces costs, and enhances overall performance while freeing up human resources for more strategic and creative endeavors.

Benefits of Robotic Automation

The adoption of robotic automation in manufacturing offers numerous benefits. Firstly, it significantly increases productivity and operational efficiency. Robots can work at a faster pace than humans, leading to higher output levels and shorter production cycles. Moreover, automation eliminates human errors, resulting in improved product quality and consistency.

Secondly, robotic automation enables cost savings and provides a substantial return on investment. While the initial implementation costs may be significant, the long-term benefits outweigh them. Robots can operate 24/7 without fatigue, reducing labor costs and increasing overall production capacity.

Applications of Robotic Automation in Manufacturing

Robotic automation finds applications in various aspects of manufacturing. One common use is in assembly and production line automation. Robots can handle repetitive tasks, such as assembling components or soldering, with precision and speed. This helps streamline the production process and reduces the risk of errors.

Another area where automation excels is material handling and logistics. Robots equipped with sensors and vision systems can efficiently transport materials, load and unload products, and organize warehouse operations. This minimizes manual labor and optimizes logistics operations.

Quality control and inspection are critical in manufacturing, and robotic automation plays a crucial role in this domain. Robots can perform inspections using advanced sensors and cameras, identifying defects and anomalies with high accuracy. This ensures consistent product quality and reduces the likelihood of faulty items reaching customers.

Challenges and Limitations of Robotic

Despite its numerous benefits, robotic automation also presents challenges and limitations. One of the primary challenges is the initial implementation cost. Acquiring and integrating robotic systems can require a substantial investment, especially for small and medium-sized enterprises. However, it’s essential to consider the long-term cost savings and increased productivity that automation brings.

Another challenge is the complexity of programming and maintenance. Robots require skilled technicians and engineers to program and maintain them. Developing intricate algorithms and ensuring the smooth functioning of the robots can be a time-consuming and complex task. However, advancements in user-friendly programming interfaces are making it easier for operators to interact with and control robotic systems.

Furthermore, concerns regarding job displacement and unemployment arise with the increasing adoption of automation. As robots take over repetitive and mundane tasks, some jobs traditionally performed by humans may become obsolete. However, it’s crucial to note that automation also creates new job opportunities, particularly in roles that require expertise in robotics programming, maintenance, and oversight.

The Future of Robotic Automation

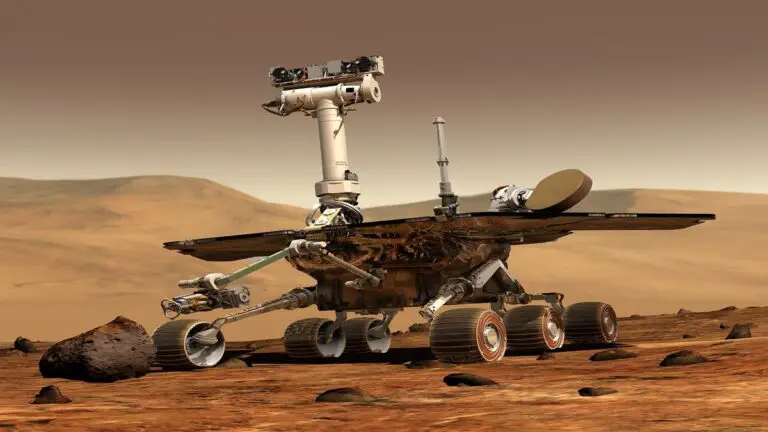

The future of robotic automation is promising, with several exciting developments on the horizon. One significant trend is the emergence of collaborative robots, also known as cobots. Unlike traditional industrial robots that operate in isolation, cobots can work alongside humans, enhancing productivity and safety. These robots are designed to be easily programmable and flexible, allowing for dynamic interaction and collaboration between humans and machines.

Moreover, the application of robotic automation is not limited to manufacturing alone. It is expanding into non-manufacturing sectors such as healthcare, agriculture, logistics, and even household chores. From robotic surgical assistants to autonomous delivery drones, automation is revolutionizing various industries and reshaping the way we live and work.

Overcoming the Challenges and Embracing Automation

To fully harness the potential of robotic automation, it is essential to overcome the challenges associated with its implementation. Investing in workforce training and education is critical. Providing individuals with the skills and knowledge needed to work alongside robots and adapt to the changing work environment will be crucial for future success.

Public policies and regulations also play a vital role. Governments need to establish frameworks that promote responsible automation practices, ensuring ethical considerations, and safeguarding workers’ rights. Collaborative efforts between industry stakeholders, policymakers, and academia are necessary to establish guidelines that support the responsible integration of automation in various sectors.

Conclusion

As technology continues to advance, the integration of robotics and automation systems will shape the future of manufacturing, service sectors, and other industries, leading to increased productivity, improved workplace conditions, and greater overall economic growth. Embracing and adapting to this revolution will be crucial for organizations to stay competitive and thrive in the dynamic landscape of tomorrow. The continued development and application of robotic automation hold the potential to unlock new levels of efficiency, productivity, and innovation, ushering in a new era of manufacturing and beyond.

Frequently Asked Questions (FAQs)

Is robotic automation limited to large-scale manufacturing industries?

Robotic automation is not limited to large-scale manufacturing industries. While it has been widely adopted in sectors like automotive and electronics, smaller businesses can also benefit from automation. There are robotic solutions available that are tailored to the needs and budgets of small and medium-sized enterprises.

Will robotic automation eliminate the need for human workers in manufacturing?

Robotic automation is designed to augment human workers, not replace them entirely. While some tasks may be automated, human workers play a crucial role in overseeing operations, performing complex tasks that require cognitive skills, and ensuring the smooth functioning of robotic systems.

How can companies ensure a smooth transition to robotic automation?

A smooth transition to robotic automation requires careful planning and implementation. It is crucial for companies to assess their specific needs, conduct thorough research on available technologies, and invest in proper training for employees. Collaborating with experienced system integrators and consulting experts in the field can also facilitate a successful transition.

What are the ethical considerations associated with robotic automation?

Ethical considerations in robotic automation include issues such as job displacement, data privacy and security, and the impact on societal well-being. It is important for companies to consider the potential consequences of automation and take measures to minimize negative impacts, ensure transparency, and address ethical concerns proactively.

How can automation benefit other sectors beyond manufacturing?

Automation has the potential to benefit various sectors beyond manufacturing. For example, in healthcare, robots can assist in surgeries and perform repetitive tasks, allowing medical professionals to focus on critical aspects of patient care. In logistics, automation can streamline warehouse operations and improve supply chain efficiency. The possibilities extend to agriculture, construction, and even household tasks, where automation can enhance productivity and safety.