Galvanic isolation is a fundamental concept in electrical engineering that plays a crucial role in ensuring compliance with safety regulations and reducing the risk of electrical hazards. By providing a physical barrier between different electrical circuits, it helps protect personnel, equipment, and systems from potential dangers. This article explores the importance of galvanic isolation in maintaining electrical safety, its applications in various industries, and the standards and guidelines associated with its implementation.

Page Contents

Understanding Galvanic Isolation

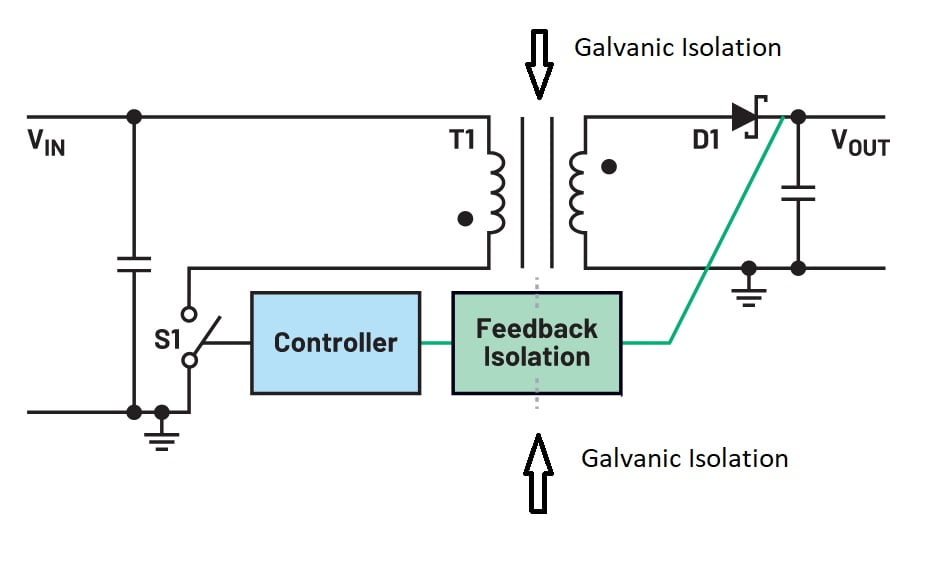

Galvanic isolation is a technique used to separate electrical circuits by using isolation barriers such as transformers, optocouplers, or capacitors. The primary purpose is to prevent the direct flow of electrical current between two circuits while allowing the transmission of signals or power. This isolation eliminates the risk of electric shock, minimizes the potential for short circuits, and protects sensitive equipment from voltage surges or transient events.

Importance in Electrical Safety

It plays a vital role in maintaining electrical safety in various scenarios:

1. Protection Against Electric Shock: It prevents the transfer of electric current between different parts of a system, reducing the risk of electric shock to personnel. It is particularly crucial in applications where individuals come into direct contact with equipment or in systems with high voltage potentials.

2. Minimizing Ground Faults: By isolating circuits, It helps prevent ground faults that can occur due to faulty wiring, insulation breakdown, or equipment malfunction. It reduces the possibility of electrical current flowing through unintended paths, ensuring the safety of both personnel and equipment.

3. Mitigating Transient Events: It protects against voltage surges, transient events, and electromagnetic interference (EMI). It prevents these disturbances from propagating across different circuits, safeguarding sensitive components and preventing damage to equipment.

4. Avoiding Ground Loops: It eliminates ground loops, which can occur when multiple devices or systems share a common ground reference. Ground loops can introduce noise, distort signals, and pose safety risks. By isolating the circuits, galvanic isolation breaks the ground loop paths, ensuring clean and accurate signal transmission.

Why is it called “Galvanic Isolation”?

The term “galvanic isolation” originates from the concept of galvanic cells, which are electrochemical cells that convert chemical energy into electrical energy. Galvanic cells were first discovered by Luigi Galvani in the 18th century, and the term “galvanic” has been used in various contexts related to electricity and electrochemistry ever since. In the case of galvanic isolation, the term refers to the prevention of galvanic or electrochemical currents from passing between two or more circuits or systems. These currents can cause various problems, such as corrosion, electrolysis, and electrical hazards, and galvanic isolation is used to mitigate these issues. The term “galvanic isolation” has become widely adopted in the field of electrical engineering to describe this technique.

Components Involved

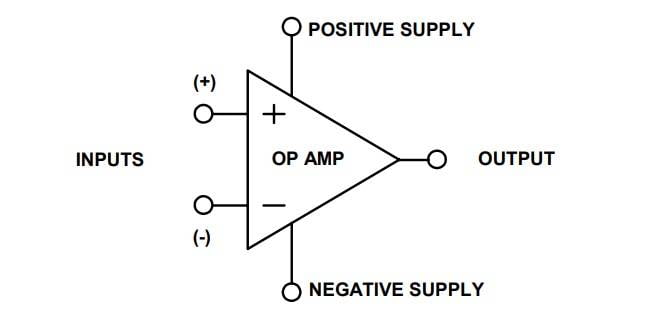

To achieve galvanic isolation, various components come into play. Transformers, optocouplers, and isolation amplifiers are commonly used to create the necessary electrical separation.

Transformers

Transformers use magnetic coupling to transfer energy between circuits without a direct electrical connection. They are widely employed in power distribution systems.

Optocouplers

Optocouplers use light to transmit signals across the isolation barrier. This method is effective in applications where electrical signals need to be transmitted without a physical connection.

Isolation Amplifiers

Isolation amplifiers provide electrical isolation while amplifying signals. They find applications in situations where signal integrity is crucial.

Applications in Various Industries

It finds wide-ranging applications across different industries:

1. Power Distribution and Energy Systems: It is essential in power distribution networks, including transformers, power supplies, and renewable energy systems. It ensures safety, prevents voltage transients, and protects equipment from potential harm.

2. Medical and Healthcare: It is critical in medical devices, such as patient monitoring systems, surgical equipment, and diagnostic devices. It safeguards patients and medical professionals from electrical hazards and ensures the accuracy and reliability of measurements.

3. Industrial Automation: It is extensively used in industrial automation and control systems. It separates different parts of the system, such as sensors, actuators, and control circuits, ensuring safety, noise immunity, and proper system functionality.

4. Telecommunications and Networking: It is employed in telecommunications and networking equipment, including modems, routers, and switches. It protects against electrical surges, prevents ground potential differences, and ensures reliable data transmission.

5. Transportation and Automotive: It plays a crucial role in electric vehicles (EVs) and hybrid electric vehicles (HEVs). It ensures the safety of the vehicle’s electrical system, protects against voltage transients, and maintains signal integrity.

Standards and Guidelines

To ensure proper implementation and maintain electrical safety, several standards and guidelines have been established. These include:

- IEC 60601-1: This standard focuses on medical electrical equipment and systems, outlining requirements for galvanic isolation to ensure patient safety and protect against electrical hazards.

- IEC 60950-1: It covers information technology equipment, specifying safety requirements, including galvanic isolation, to protect users and prevent electrical risks in the IT industry.

- IEC 60079: This standard addresses equipment used in explosive atmospheres, such as oil refineries or chemical plants, and provides guidelines for implementing galvanic isolation to mitigate ignition risks.

- UL 61010: Underwriters Laboratories (UL) Standard 61010 is applicable to laboratory and test equipment. It includes requirements for galvanic isolation to ensure operator safety and equipment protection.

- IEEE 1584: This standard focuses on arc flash hazard calculations in electrical systems. Galvanic isolation can be employed to reduce the risk of arc flash incidents and protect personnel.

These standards provide guidelines for implementing galvanic isolation effectively and maintaining electrical safety in specific industries and applications. Compliance with these standards is essential to ensure proper design, installation, and operation of galvanic isolation systems.

Conclusion

Galvanic isolation is a crucial technique for enhancing electrical safety and preserving signal integrity in various industries. It protects against electric shock, minimizes ground faults, mitigates transient events, and avoids ground loops. Compliance with relevant standards and guidelines ensures the proper implementation of galvanic isolation, reducing the risk of electrical hazards and promoting safe and reliable operation of electrical systems.